Laser marking machine for marking on titanium steel materials

Laser marking machine for marking on titanium steel materials

Titanium steel, also known as 316L stainless steel, is actually the same material as 316L stainless steel, but the names of regions and businesses are different. Resistant to strong acids, alkalis, color, non-allergic, hard, non-deformable, bright. It is widely used in medicine, luxury watches, pens and industry. It has a wide range of applications in the market, and there are many places where laser marking machines are needed. For example, titanium steel products usually need to be marked with logos, letterings, and marking codes.

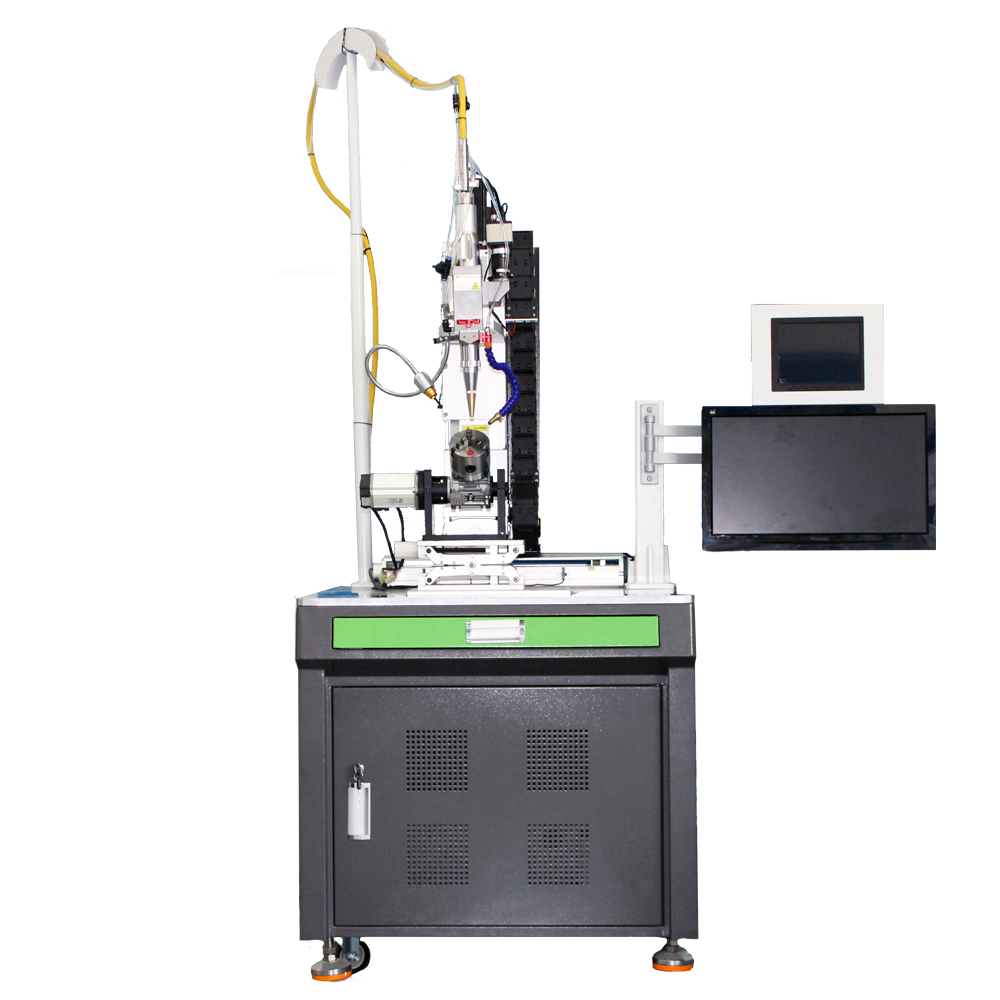

The laser marking machine has a wide range of adaptability. It can mark metal and most non-metal materials, such as stainless steel, aluminum alloy, copper, iron, plastic, acrylic, wood, leather, glass, PCB board, etc. Yes, its minimum line width is only 0.04mm, the lettering is high, the logo marked on the titanium steel is clear and exquisite, durable, does not fade and corrode, and has strong anti-counterfeiting functions.

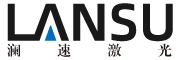

The combination of laser marking machining system and computer numerical control technology can constitute a highly automated processing equipment, which can print a variety of text, symbols and patterns, easy to design marking patterns with software, change the content of marked websites, adapt to modern production efficiency, fast pace Requirements.

Laser marking machine has fast marking speed and one-shot marking, low energy consumption, so low running cost. Although the equipment investment of laser marking machine is larger than that of traditional marking equipment, the laser marking is much lower in terms of running cost. No internal stress will be generated on the workpiece to ensure the original accuracy of the workpiece. No corrosion to the work surface, no tool wear, no poison, no pollution